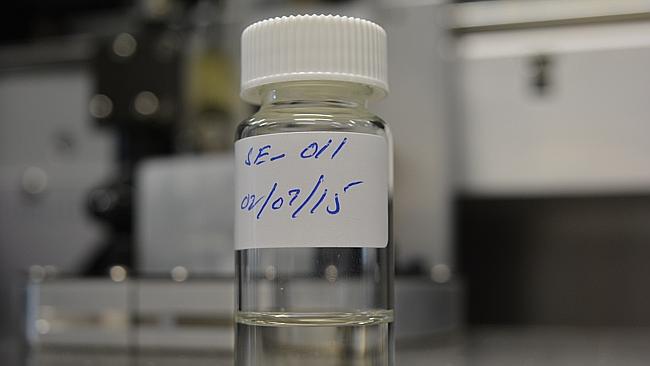

SYDNEY (Web Desk) – Australian scientists have created ink that can remember vast amounts of information. The memory ink can be printed on to surfaces by an inkjet printer.

It may look transparent to the naked eye, but the ink contains microscopic ceramic cubes that are 10,000 times thinner than a human hair. The cubes store information digitally – as a series of zeros and ones, as traditional memory does, The Australian reports.

Sean Li, from the University of NSW School of Materials Science and Engineering, said the ink would be part of a project to build a totally transparent computer that could be attached to objects such as TV screens, flexible displays, glass screens and next-generation wearables.

Professor Li said scientists were working on transparent transistors, a transparent power supply was halfway there, transparent memory was now developed, as was a transparent display. Together, these comprised a transparent computer.

The ceramic cubes in the ink are made from the rare earth mineral cerium oxide, and each is about 10 nanometres thick. In concept, two trillion cubes could fit in a memory cell configuration the size of a standard postage stamp, Professor Li said.

He said when placed in a solution and deposited on to a conductive surface using an inkjet printer, the cubes self-assemble: they form a co-ordinated square array, then stack on top of each other like Lego, building up layer by layer.

Professor Li, who led the team developing the new material with UNSW colleagues Dr Adnan Younis and Dr Dewei Chu, said the nanocubes had unique physical properties for microelectronics, and could be used for what’s known as resistive random access memory (RRAM) devices.

ASX-listed firm Strategic Elements has been granted a licence to develop and commercialise the technology.

Managing director Charles Murphy said the printed electronics industry was projected to grow to about $US78 billion by 2023.

“From our perspective, we had a technology with a global market that is unlike anything else available, developed by a team of passionate researchers at the No 1 materials science school in the country,” he said.

“This is a completely different way of potentially providing high performance memory.”

Mr Murphy said the technology was not limited to inkjet printing. Potentially it could be adapted to other hi-tech fabrication processes, such as aerosol jet printing and roll-to-roll processing.

the next three months, the company will work with UNSW to optimise the nanocube ink and print memory cells on to silicon, flexible plastic and glass, testing aspects of their performance.

The team is also intending to work with circuit designers to assist in development of a memory device prototype.